New Innovations in Artificial Vision Systems in the Infrared Enabled by CMOS Si Sensors

Dr. Abhijit Biswas

Following the successful launch of the ECL Series, Hiden Analytical is highlighting the core features that make this electrochemical toolkit a powerful platform for HPR-40 DEMS users engaged in real-time analysis of gases and volatile species in electrochemical research. (read for more)

Princeton Scientific Corporation is excited to announce the launch of its latest innovations in material science and engineering products. These new offerings, available as of January 2026, are designed to meet the demands of researchers, scientists, professors, and industry professionals worldwide. (read for more)

TDK Corporation (TSE:6762) announces that it has acquired the assets related to the power business of QEI Corporation (Headquarters: Williamstown, New Jersey, USA hereinafter “QEI”). QEI designs and manufactures advanced RF power generators and impedance matching networks for critical plasma processing in semiconductor production. (read for more)

In a “hybrid route” combining evaporation and blade-coating to deposit perovskite solar cells on silicon bottom cells, they produced tandem solar cells with efficiencies approaching 28 percent. (read for more)

Since 2000 Vacuum Technology & Coating Magazine has been the industry's leading source for the latest articles, news, and product and service information. Below we describe some of the terms that you will find in a typical issue of VT&C.

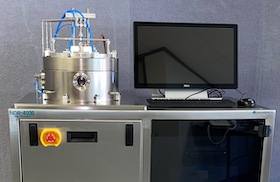

Vacuum Coating (Vacuum Deposition and Thin Film Deposition) is the process of depositing a film or other material atom by atom or molecule by molecule onto a surface in a low pressure environment or vacuum.

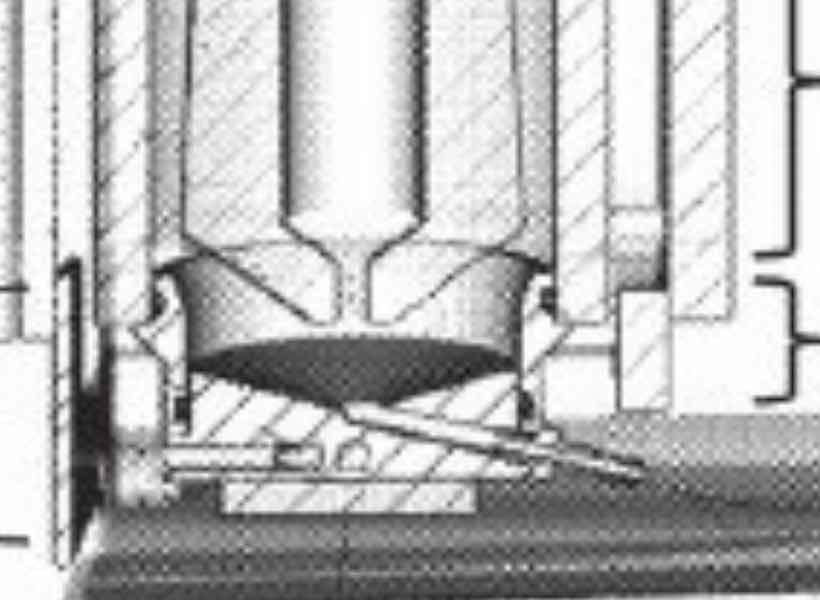

Physical Vapor Deposition or PVD refers to vacuum deposition methods which involve the material (which is being deposited) going from a condensed phase to a vapor phase and then to a thin film condensed phase. Sputtering and evaporation are common PVD processes.

Sputtering refers to a type of process used to deposit thin films and employs a plasma to bombard and eject atoms from a target source.

Evaporation refers to the heated source material being evaporated in a vacuum. Vacuum allows vapor particles to travel directly to the target object, where they condense back to a solid state. (called a Deposition Source) refers to a type of process used to deposit thin films and employs a plasma to bombard and eject atoms from the target source (called a Deposition Source).

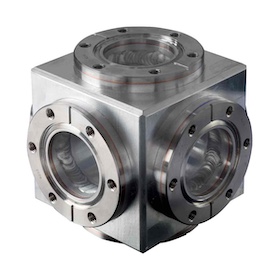

Vacuum Hardware refers to the types of hardware and components that are used in the vacuum process. There are many types of hardware used in this process, some examples are flanges, fittings, seals, valves, and chambers.

Thin Film Metrology involves determining the optimal thickness, composition and/or condition of a coating through various techniques and mathematical calculations.

Gas Analytical Systems are used in the analysis of residual gases within a low pressure environment or vacuum.

Vacuum Pumps are devices that remove gas atoms and molecules for the purpose of leaving behind a partial vacuum. Some examples of types of vacuum pumps are rotary vane pumps, diaphragm pumps, and scroll pumps.

Every issue of VT&C includes a product showcase focused on a specific topic relevant to Vacuum Processing, please see our 2026 editorial calendar which lists the topic for each issue.